Theory of operation

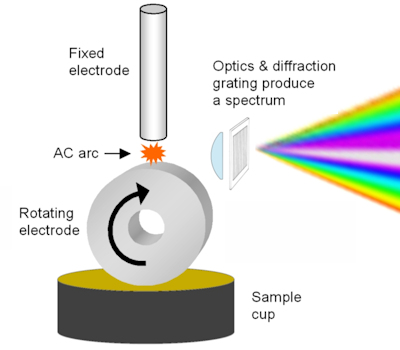

Optical emission spectroscopy using a rotating disc electrode

Our OES spectrometers employ the time-proven rotating disc electrode (RDE) sample delivery technique. This technique remains the most effective and widely accepted method for detection and quantification of wear metal particles, contaminants, and additives.

The rotating electrode “wicks up” sample to the point where a high-voltage arc occurs between the rotrode and a fixed electrode. The resulting plasma vaporizes the sample and imparts sufficient energy to produce atomic emission of elements in the sample. Photons in the visible and ultra violet light region are emitted by these excited elements and then separated into a spectrum using a high-resolution diffraction grating.

Intensities of resulting characteristic wavelengths of light, corresponding to the elements of interest, are then converted by photo detectors into electrical signals, which are processed and displayed as results. Intensity, of these emissions, is proportional to elemental concentration. The entire process is completed in about 30 seconds, with the only consumables being: sample containers (bottle caps), rod and disc electrodes (rods can be reused), and reference standards for periodic calibration.